In the competitive world of manufacturing, efficiency, accuracy, and quality control are paramount. Companies are continually searching for innovative technologies to enhance their production processes. One such technology that has gained significant traction is the machine vision system. By integrating machine vision systems into their operations, manufacturers can achieve superior object detection and defect detection, particularly in tasks such as product counting and quality control. This article delves into the top benefits of using machine vision systems in these critical areas.

Understanding Machine Vision Systems

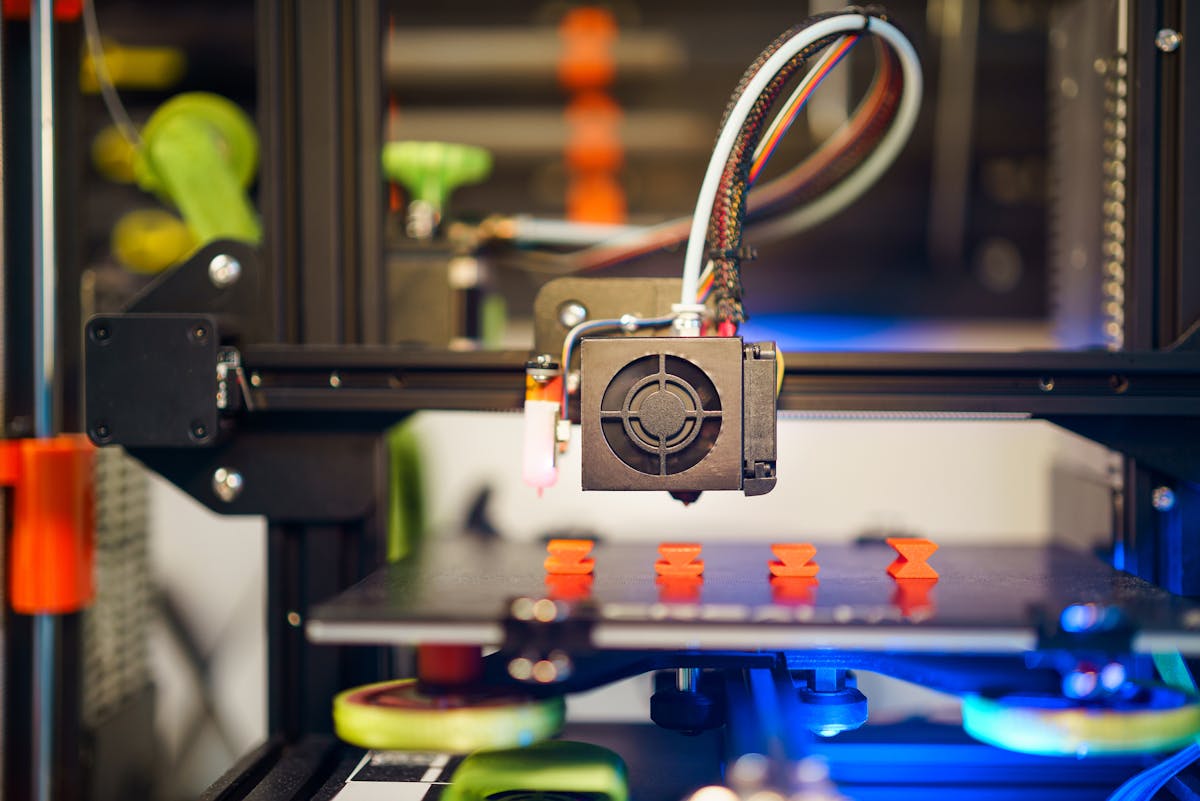

A machine vision system comprises cameras, lighting, sensors, and software designed to capture and analyze visual information. These systems interpret images to make decisions based on predefined criteria, mimicking human vision but with much higher speed, precision, and consistency. Machine vision systems are essential in applications requiring meticulous inspection, accurate counting, and stringent quality control.

Benefits of Machine Vision Systems in Product Counting

Product counting is a fundamental task in many manufacturing processes. Accurate counting ensures proper inventory management, packaging, and shipment, directly impacting the overall efficiency and profitability of a business. Here are the key benefits of using machine vision systems for product counting:

High-Speed Counting: Machine vision systems can process images at incredibly high speeds, enabling real-time product counting. This capability is particularly beneficial in high-volume production environments where traditional manual counting methods are impractical. By ensuring rapid and accurate counting, manufacturers can maintain high throughput rates and meet production targets more efficiently.

Enhanced Accuracy: The precision of machine vision systems surpasses that of manual counting. High-resolution cameras capture detailed images, and advanced algorithms analyze these images to count products with exceptional accuracy. This minimizes errors that could lead to inventory discrepancies, ensuring that the correct number of products is packaged and shipped.

Consistency: Unlike human operators who may experience fatigue or inconsistency, machine vision systems provide uniform results. Once calibrated, these systems perform counting tasks with the same level of accuracy and reliability every time, eliminating variations that can occur with manual methods.

Automation and Integration: Machine vision systems can be seamlessly integrated into automated production lines, working in conjunction with other machinery such as conveyors and robotic arms. This integration facilitates continuous and unattended counting, reducing the need for manual intervention and freeing up personnel for more strategic tasks.

Flexibility: Machine vision systems are adaptable and can be configured to count a wide range of products, regardless of their size, shape, or color. This flexibility makes them suitable for diverse manufacturing environments, from electronics and automotive parts to food and beverage items.

Benefits of Machine Vision Systems in Quality Control

Quality control is crucial for maintaining product standards and customer satisfaction. Defective products can lead to costly recalls, damage to brand reputation, and loss of customer trust. Machine vision systems offer several advantages in enhancing quality control through effective

Accurate Defect Detection: Machine vision systems can detect a wide variety of defects, including surface imperfections, dimensional inaccuracies, and structural flaws. These systems utilize high-resolution imaging and sophisticated algorithms to identify defects that may be too subtle for the human eye to detect. This ensures that only products meeting the highest quality standards reach the market.

Real-Time Inspection: One of the significant advantages of machine vision systems is their ability to perform real-time inspections. As products move along the production line, machine vision systems continuously monitor for defects, providing immediate feedback and allowing for quick corrective actions. This capability helps prevent defective products from advancing further in the production process, reducing waste and rework.

Comprehensive Coverage: Machine vision systems can inspect products from multiple angles and under various lighting conditions, offering comprehensive coverage that traditional inspection methods cannot match. This all-encompassing approach ensures that defects are detected no matter where they are located or how subtle they may be.

Reduction of False Positives: Traditional defect detection methods can sometimes generate false positives, leading to unnecessary rework or scrap. Machine vision systems use advanced algorithms to minimize false positives, ensuring that only genuine defects are flagged for further inspection or correction. This reduces unnecessary costs and improves overall efficiency.

Data Collection and Analysis: Machine vision systems generate valuable data during inspections. This data can be analyzed to gain insights into the production process, identify trends, and predict potential issues before they arise. Manufacturers can use this information to optimize production parameters, improve processes, and achieve continuous improvement in quality control.

Additional Benefits of Integrating Machine Vision Systems

Beyond product counting and quality control, integrating machine vision systems offers several other benefits that contribute to overall operational efficiency:

Cost Savings: By automating counting and inspection tasks, machine vision systems reduce the need for manual labor, leading to significant cost savings. Additionally, by catching defects early in the production process, these systems help minimize waste and rework, further reducing costs.

Improved Product Quality: Consistent and accurate object detection and defect detection lead to higher quality products. This not only reduces the likelihood of customer complaints and returns but also enhances the overall reputation of the brand. High-quality products result in increased customer satisfaction and loyalty.

Scalability: As production demands increase, machine vision systems can easily scale to meet these needs. Whether a manufacturer is producing a few hundred or several thousand units per hour, machine vision systems can be configured to handle the load efficiently. This scalability ensures that efficiency gains are maintained even as production volumes grow.

Compliance and Traceability: Machine vision systems can help manufacturers comply with industry standards and regulations by ensuring that all products meet specified quality criteria. Additionally, these systems can provide traceability by documenting inspection results, which can be crucial in industries such as pharmaceuticals and food processing.

Enhanced Safety: By automating inspection and counting tasks, machine vision systems can improve workplace safety. Reducing the need for manual handling of products minimizes the risk of injury to workers, creating a safer working environment.

Future Trends in Machine Vision Technology

The future of machine vision technology is promising, with several trends poised to further enhance its capabilities:

Artificial Intelligence (AI) Integration: The integration of AI with machine vision systems is revolutionizing object detection and defect detection. AI-powered systems can learn from past inspections, continuously improving their accuracy and adaptability. This allows for more complex tasks to be performed with greater precision.

Edge Computing: Edge computing involves processing data closer to where it is generated, rather than relying on centralized cloud servers. For machine vision systems, this means faster processing times and reduced latency, enabling real-time decision-making and quicker responses to changes on the production line.

3D Vision Systems: The development of 3D vision systems allows for more detailed and accurate inspections, particularly in industries where products have complex geometries or where depth perception is crucial. This advancement is set to expand the capabilities of machine vision systems even further.

Collaborative Robots (Cobots): Cobots equipped with machine vision systems are becoming increasingly common in manufacturing environments. These robots can work alongside human operators, combining the strengths of both to enhance production efficiency and flexibility.

Industry 4.0 and IoT Integration: The integration of machine vision systems with Industry 4.0 technologies and the Internet of Things (IoT) is set to revolutionize manufacturing. By connecting machine vision systems to a network of smart devices, manufacturers can gain real-time insights into their production processes, optimize operations, and achieve unprecedented levels of efficiency.

Integrating machine vision systems into manufacturing operations offers numerous benefits, particularly in tasks such as product counting and quality control. These systems provide high-speed, accurate, and consistent performance, enhancing efficiency and ensuring that only the highest quality products reach the market. As technology continues to evolve, the capabilities of machine vision systems will only expand, making them an essential tool for any manufacturer looking to stay competitive. Investing in machine vision technology today is a strategic move that will pay dividends in the form of increased efficiency, reduced costs, and superior product quality.